Sacrifices need to be made for life to be sustainable

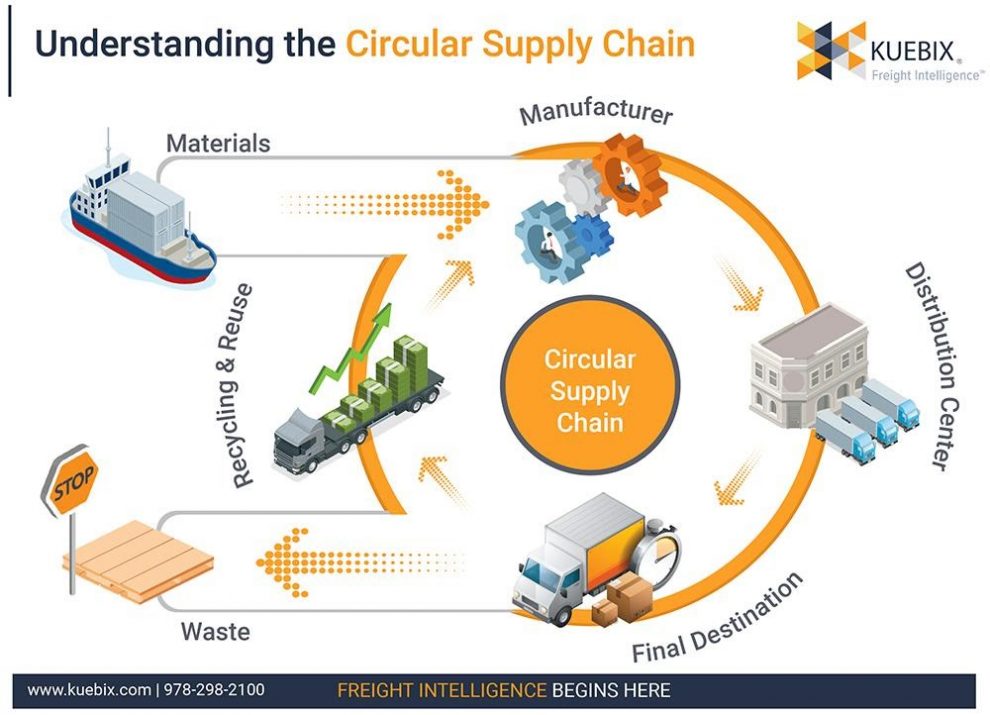

The normal supply chain is where the materials are produced, used, and then after their lifetime dumped into landfills and other sources in order to discard them. It also damages the environment it is disposed of. In 2019 a set of divers who went on dive in the Mariana trench found a plastic bag in it. Mariana trench is considered the deepest point on earth. Examples such as this show why people are turning their attention to circular supply chains where the materials are reused and recycled once their time of use is over. Despite people have become interested in this concept only 9% of the plastic waste is being able to be recycled effectively.

In the previous studies that have been conducted, it was found that circular supply chains tend to be more efficient compared to the normal ones. So then now the question arises that if so, why are these supply chains so rarely being used in the current market structures?

To understand this let’s take a look at the following examples:

Aluminium cans are one of the most recycled products in the market. To understand why this is so let’s take an in-depth look at it. The people who collect the cans get as much as 0.05 pounds for each can which is an incentive for them. The people who collect the cans from the users and sell it to the companies also get a good profit. The companies in turn recycle this and use them which is profitable for them rather than producing new ones. Here everyone gets an incentive so circular supply can be successful for this product.

The same can be said of office furniture and products as such. They can be easily recycled which is why circular supply can be effective for them. By adding new parts or repairing the damaged products is more profitable for the people rather than buying a new one.

Generally,not all the products in the market can be recycled and reused in the above-mentioned manner. Production is centralized in order to achieve two main goals i.e., performance via specialization of parts and designs that add functionality to it and economic efficiency which consists of large plants that share fixed costs and deliver to a wide area with an elaborate distribution system.

Due to this reason, the expense incurred due to a circular economy is quite large which the companies are not willing to bare.

This is why circular supply chains are rare in a market structure. For this to work the companies will have to cut back on some of their profits and the people will get lower quality goods due to the usage of highly recyclable materials. For the betterment of the planet, future sacrifices need to be made.

Article source: hbr.com

Image credit: supplychain247.com

Add Comment